Outline of stamping out processing

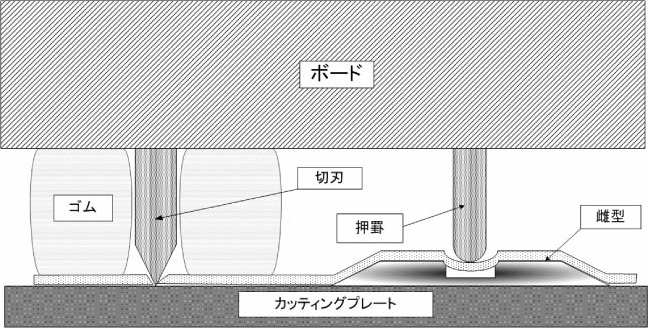

It is processing method to stamp out arbitrary shape by placing, and pressurizing material processed between a steel rule die and a counter plate. There are 3 methods.

Victorian Type: The steel rule die is installed in a V-shaped board, and the paperboard to be processed is placed and stamped out.

Flatbed Type: The steel rule die is fixed up, and the paperboard is stamped out by moving the counter plate up and down.

Rotary Type: The paperboard is stamped out by passing it between two rotating cylinders (one side is the steel rule die).

Kind of the Steel Rule Die

The kind of the steel rule die changes into what shape what kind of material according to whether you want to stamp it out. It explains 3 typical cases that our company is making here.

At a general stamping out processing such as packages and cards

Dieboard used -> Wooden Dieboard (Dieboard that buried metallic blade under wooden board)

Machine used -> Flatbed type automatic stamping out machine or manual stamping out machine

A minute character and a minute curve cannot be processed, but if the blade is used properly, it is possible to stamp it out from the thin paper to the thick paper. The crease and emboss are applied at the same time. The dieboard is set in stamping out machine, pressure is put from the under, and the paperboard is stamped out. Stamping out of 300,000 times or more is possible by one dieboard.

(It changes according to the condition of the material and the blade.)

At a stamping out of a minute processing + thin paper such as seals

Dieboard used -> Metallic Dieboard (All dieboard like foundation and blade, etc. made from metal)

Machine used -> Rotary cutter or flatbed type stamping out machine

It uses it to stamp out a minute character or a minute pattern that not expressible in wooden dieboard. However, being able to stamp out is up to a thin paper of about 0.6mm. In general, one is wrapped around the cylindrical steel that is called a cylinder, and it cuts it while rotating.

At a stamping out thich board material such as plastic corrugated cardboards

Dieboard used -> Wooden Dieboard (Dieboard that buried metallic blade under wooden board)

Machine used -> Roller or flatbed type automatic stamping out machine

Advantage and disadvantage of stamping out processing

Advantage

It is possible to mass-produce it with cheap dieboard.

It is possible to mass-produce it with cheap dieboard.

Moreover, it is a story of the cookie. Round shape or stelliform is not surely made well when cutting it out with the hand either. Much more, even if you make it how much holding out, the elephant and the giraffe become indistinguishable with the hippopotamus. But it is possible to make it in a type the same even by degrees how many until it breaks as long as there is dieboard. This is the first advantage "The one the same even by degrees how many can be made as long as there is a dieboard".

Because the cookie that you had made was very delicious, the shop decided to be opened. The rumor calls the rumor, and it prospers greatly at once. It is not in time even if it makes or it makes it. "It is an easy victory if it stamps it out at a time a lot" (It is surely wrong as the patissier). The dieboard that was able to stamp out ten products was made at a time. Ten times work once and productive capacity it. This is the second advantage "A lot of products can be made once by combining plurals".

Disadvantage

Dieboard can be needed without fail for the processing, and only the plane one be made.

Because sales of the cookie was good, sales of the cake were started. There was a bulk order of Montblanc, and you who had gotten the taste thought, "Let's make this from stamping out". The result is clear. Of course, it doesn't go well. This is the first disadvantage "a solid thing cannot be stamped out = it is limited to the plane one". Only one was ordered when sales of the cake were abandoned, and it squeezed it to one cookie. It doesn't go well in the hand as written before, unavoidably, a dieboard decided to be made for one. This is the second disadvantage "a dieboard is necessary also for making one".

Did you understand above? It can actually do more though it talked as an example of the cookie to keep easy. It introduces it in detail in "High Grade Packages & Dieboards Case".

Basic Structure of Dieboard